Welcome to the official website of Shenzhen Bubujing Technology Co., Ltd.

-

contact number

contact number15013815515

-

email address

email address -

office hours

office hoursMon-Sat: 9.00am to 18.00pm

Welcome to the official website of Shenzhen Bubujing Technology Co., Ltd.

15013815515

Mon-Sat: 9.00am to 18.00pm

Shenzhen Bubujing Technology Co., Ltd.

Mobile: 15013815515

Fixed line: 0755-82886755

Email: bbj001@szbbj.cn

Website: www.bbjconn.net

Factory address: Building 124-128, Seventh Industrial Zone, Mashan Tou Community, Matian Street, Guangming District, Shenzhen

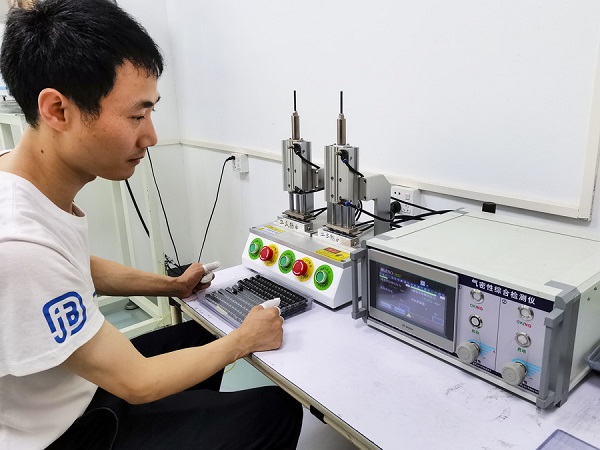

Type-C connector detection and test process analysis

With the expansion of the functions of electronic equipment,Type-C connectorIt has been widely used in various types of electronic products. However, in order to ensure the performance and quality of the connector, manufacturers need to carry out a series of inspections and tests. This article will deeply analyze what Type-C connectors need to go through before delivery Inspections or tests, and the purpose and procedures of those tests.

1. Appearance inspection

First of all, Type-C connectors need to be inspected for appearance. The purpose of appearance inspection is to ensure that the size, shape and color of the connector meet the standards and customer requirements. In appearance inspection, the operator will check the appearance of the connector, plug, socket , whether the conductors and other parts are damaged or deformed, and also check whether the accessories, signs and packaging of the connector are complete. If any problems are found, the operator will return the connector to the repair or replacement link.

2, electrical function test

Electrical function test is one of the core stages of Type-C connector detection. Its main purpose is to ensure that the connector can work normally and meet the specifications. The electrical function test simulates the actual application environment to detect the signal transmission of the connector, power adaptation, Cable test, compatibility test, etc. This test stage is also an opportunity to test various electrical performance indicators, such as contact resistance, insertion force, socket and plug insertion, retention force, power supply voltage, signal transmission, impedance and other parameters.

3, mechanical test

The Type-C connector also needs to be mechanically tested to ensure that its physical properties meet the engineer's design requirements. During this testing phase, mechanical parameters such as pressure, twist, and tension must be measured and recorded. In addition, mechanical performance test methods are also required. Validation is performed to ensure test accuracy and repeatability.

4, Environmental testing

Environmental testing is a very important test stage, the purpose is to detect the durability and adaptability of the connector. In this test stage, the connector needs to experience various environmental factors, such as temperature changes, humidity, pressure, vibration, shock, ultraviolet rays Radiation, etc. After the environmental test, the operator needs to evaluate the test results, including mechanical properties, electrical properties, appearance changes of connectors and service life of accessories, etc.

5, certification test

According to international standards and customer requirements, Type-C connectors also need to undergo certification testing. Certification testing is for specific target markets, including European CE certification, American FCC certification, Canadian IC certification and Chinese CCC certification. These certifications The purpose is to ensure that the connector complies with international standards and regulations, and meets customer-specific regulations and preferential policies.

in conclusion:

In the Type-C connector inspection and testing process, each step is very critical. Appearance inspection can ensure that the size, color, and shape meet the requirements; electrical function testing can test the electrical performance of the product; mechanical testing can test the mechanical properties of the product; environmental testing It can test the durability of the product; the certification test can meet the certification requirements of the designated regional market. These test steps can ensure the high quality and stable performance of Type-C connectors, and are also the key to manufacturers' competitiveness in the market.

Mr. Lee

15013815515

No. 7 Industrial Zone, Mashantou Community, Matian Street, Guangming District, Shenzhen

(Building 124.125.128, No. 1 Industrial Park, Mashantou, Guangming Jianfa)

bbj001@szbbj.cn