Welcome to the official website of Shenzhen Bubujing Technology Co., Ltd.

-

contact number

contact number15013815515

-

email address

email address -

office hours

office hoursMon-Sat: 9.00am to 18.00pm

Welcome to the official website of Shenzhen Bubujing Technology Co., Ltd.

15013815515

Mon-Sat: 9.00am to 18.00pm

Shenzhen Bubujing Technology Co., Ltd.

Mobile: 15013815515

Fixed line: 0755-82886755

Email: bbj001@szbbj.cn

Website: www.bbjconn.net

Factory address: Building 124-128, Seventh Industrial Zone, Mashan Tou Community, Matian Street, Guangming District, Shenzhen

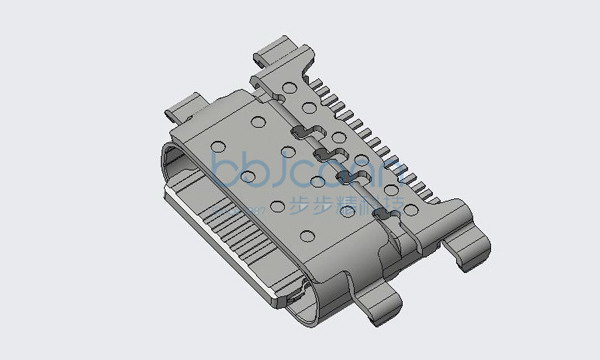

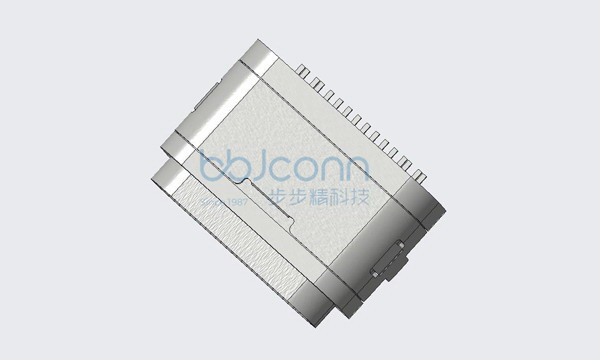

Brief description of the production process of Type-C connector

DiscussingType-C connectorThe production process requires a series of highly precise processing and assembly steps. These processes are key to ensuring the quality, performance and reliability of Type-C connectors, so the production process must be precisely controlled and quality managed. Type-C The connector is a single connector solution for data, power and A\/V applications, with a slim profile suitable for mobile devices while being durable enough for industrial applications. In 2022, the European Union also mandated The Type-C interface is uniformly adopted. As the application scenarios of Type-C connectors increase, the performance requirements for factors such as high-frequency signals, mechanical characteristics, electrical performance, and environmental changes are also constantly increasing. Therefore, manufacturers are producing related products. It is necessary to develop a complete testing and certification plan and rely on the assistance and consultation of professional laboratories to ensure that the product meets quality standards and perfectly meets functional requirements. Professional laboratories and certification agencies will conduct electrical testing, mechanical testing, environmental testing, etc. The test content is verified to ensure that the product meets the standards of the relevant association. During the verification process of the association certification and testing center, the manufacturer will also obtain production parameters, which will help in subsequent production and manufacturing.

The manufacturing process of Type-C connectors can be briefly summarized as four main steps: stamping, plating, injection molding and assembly.

The stamping stage is usually the starting point for Type-C connector manufacturing. At this stage, a large high-speed stamping machine is used to punch a thin metal strip into the plug shape of the Type-C connector. One end of the metal strip is fed into the stamping machine The front end, the other end pulls out the metal strip through the coil eccentric of the hydraulic press operating table, and stamps it into finished terminal blocks.

Next is the electroplating process (Plating) stage. After the connector pins are stamped, this stage will be entered. In the electroplating process, the electronic contact surface of the connector will be coated with various metal materials, such as electroplated nickel, electroplated Tin, half gold plating, etc. to prevent air oxidation and improve conductivity.

Injection molding (Molding) is a process in which molten plastic is injected into the membrane of a metal material and then rapidly cooled for molding. At this stage, it is necessary to ensure that the molten plastic fully fills the membrane to avoid defects such as "leakage". At the same time, it is also Detection of filled or partially blocked jack holes is required. These jack holes must be kept clean and smooth to ensure proper connection with the pins after assembly. Leaks in the box base and blocked jack holes can be easily detected using backlight technology. , making quality inspection after injection molding relatively simple and easy.

Finally, there is the assembly stage of the finished product. At this stage, the electroplated pins and the injection molded box holder are connected and assembled. There are two common ways: individual plugs and combined plugs. Individual plugs refer to each One pin is connected at a time, while a combination plug connects multiple pins to the socket at once. No matter which method is used, the manufacturer needs to check whether all plugs are leaking and correctly positioned during the assembly stage to ensure that they are plugged into the socket. The needle has no defects and inserts accurately.

The production process of Type-C connectors is a highly complex and precise process, involving multiple key steps such as material preparation, metal processing, electronic component manufacturing, welding and assembly, testing and quality control, and packaging and labeling. The key steps of these processes High precision and strict quality control are key factors to ensure the performance and reliability of Type-C connectors to meet users' high requirements for data transmission and charging.

In the ever-evolving electronics market, the production process of Type-C connectors will continue to receive attention to meet the growing market demand and provide faster and more reliable connection solutions. At the same time, the continuous innovation of production processes will also Promote the advancement of connector technology and provide more powerful connection performance for future electronic devices.

Mr. Lee

15013815515

No. 7 Industrial Zone, Mashantou Community, Matian Street, Guangming District, Shenzhen

(Building 124.125.128, No. 1 Industrial Park, Mashantou, Guangming Jianfa)

bbj001@szbbj.cn