Welcome to the official website of Shenzhen Bubujing Technology Co., Ltd.

-

contact number

contact number15013815515

-

email address

email address -

office hours

office hoursMon-Sat: 9.00am to 18.00pm

Welcome to the official website of Shenzhen Bubujing Technology Co., Ltd.

15013815515

Mon-Sat: 9.00am to 18.00pm

Shenzhen Bubujing Technology Co., Ltd.

Mobile: 15013815515

Fixed line: 0755-82886755

Email: bbj001@szbbj.cn

Website: www.bbjconn.net

Factory address: Building 124-128, Seventh Industrial Zone, Mashan Tou Community, Matian Street, Guangming District, Shenzhen

Differences between industrial-grade Type-C connectors and ordinary Type-C connectors and analysis of application scenarios

Type-C connectorIt is a high-speed transmission, multi-functional, reversible plug-in connector, and its characteristics are widely used in various scenarios. In the industrial field, with the rapid development of Industry 4.0, the requirements for industrial-grade Type-C connectors are getting higher and higher. So what is the difference between it and the ordinary Type-C connector? This article will analyze it from the following aspects.

First, the difference in shell material

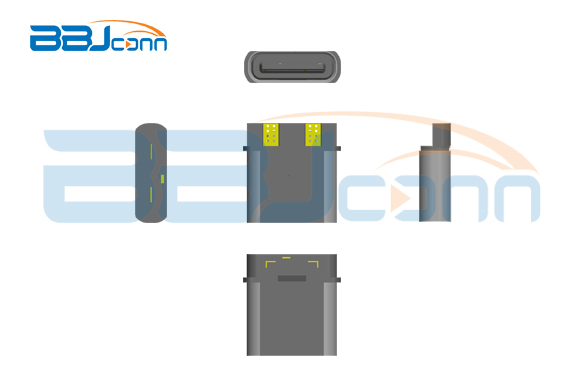

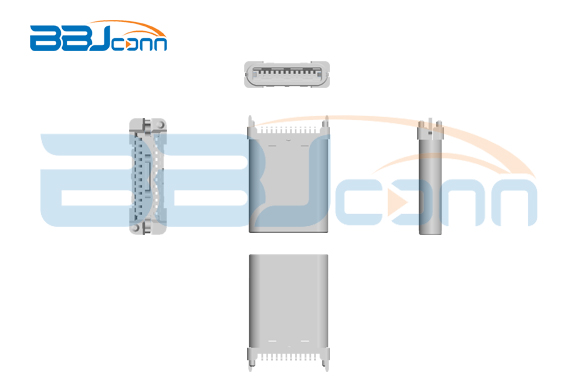

Ordinary Type-C connector shells are mainly made of plastic materials, while industrial-grade Type-C connectors use more durable metal shells, such as aluminum alloys, magnesium alloys, etc., which can better resist wear, pollution and oxidation. .Industrial-grade Type-C connectors also usually have better protection capabilities and can cope with harsher industrial environments.

2, the difference in transmission speed

The transmission speed of ordinary Type-C connectors is generally around 5Gbps (Gigabits per second), while the transmission speed of industrial-grade Type-C connectors can reach more than 10Gbps, and some can even reach 40Gbps, which also means that there are higher standards in the industrial field. Under the requirements of the industry, the industrial-grade Type-C connector has better performance.

3, the difference in reliability

In the industrial field, industrial-grade Type-C connectors pay more attention to the reliability and stability of transmission than ordinary Type-C connectors. Compared with ordinary Type-C connectors, industrial-grade Type-C connectors use higher-end Electronic components to improve the reliability of signal transmission, but also have a higher level of protection, can cope with harsher environments, such as industrial-grade Type-C connectors usually can prevent a higher level of waterproof and dustproof capabilities.

4. Differences in application scenarios

Ordinary Type-C connectors are widely used in consumer electronics, such as smartphones, tablet computers, notebook computers and other equipment. Industrial-grade Type-C connectors are more used in industrial control, robotics, automation and other industrial fields. Due to industrial The grade Type-C connector has the characteristics of waterproof, dustproof, high temperature, corrosion resistance, etc., and is widely used in key equipment in the fields of intelligent manufacturing, intelligent warehousing, automated production lines, and aerospace, military and other fields.

To sum up, there are big differences between industrial-grade Type-C connectors and ordinary Type-C connectors in terms of shell material, transmission speed, reliability and application scenarios. Industrial-grade Type-C connectors are used in industrial control , robotics, automation and other industrial fields, while ordinary Type-C connectors are widely used in the field of consumer electronics. With the rapid development of Industry 4.0, the application of industrial-grade Type-C connectors will also be more widely and deeply promoted , enjoying a broader market development prospect.

Mr. Lee

15013815515

No. 7 Industrial Zone, Mashantou Community, Matian Street, Guangming District, Shenzhen

(Building 124.125.128, No. 1 Industrial Park, Mashantou, Guangming Jianfa)

bbj001@szbbj.cn